Fasteners

Critical link between rails and sleepers

Fasteners

Fasteners are the critical link between rails and sleepers, ensuring safety and performance across diverse track conditions. Patil Group, in collaboration with global leaders in fastening technology, has built proven expertise in designing, manufacturing, and supplying advanced fastening systems for modern rail networks.

Patil Group has over two decades of experience in track fastening systems — beginning with joint ventures and the development of a local vendor base. In 2020, the Group established a dedicated fastening plant, bringing all processes under one roof and adding in-house capabilities in die tool design and heat treatment. Today, Patil Group is the largest fastening supplier for metros and a trusted partner to Indian Railways across multiple zones.

For Mainline Ballasted Track

Elastic Rail Clips

ERC clips: Mark III & V

Manufactured in Medchal

Approved by RDSO for Indian Railways and freight corridors

Production Capacity

Approximately 110,000 units per annum

GFN Liners

GFN liner production

84 lakh units per annum

RDSO approved

SKL Series

- SKL 12

- SKL 15

- System W 14 HH

System W 14

HH

(Heavy Haul)

Used in freight and heavy axle routes

Allows tension clamping and tilt protection

Reduces long-term maintenance

Lab Facilities

- World-class labs

- Fatigue testing machines

- GOM Scanner

- Salt spray testing machine

- UTM

As per STR (Schedule of Technical Requirements) of RDSO. These testing machines are not available anywhere else in India.

For Mainline Ballastless Track

Pre-assembled system suitable for all slab-track installations

Optimized for vibration and noise reduction.

Ideal for urban rail and steel structure tracks.

W Clamp

The W clamp is a resilient fastening component used in railway tracks.

It ensures secure retention of rails to sleepers—maintaining track stability under dynamic loads.

Its design allows controlled flexibility, reducing vibration and stress on the fastening system.

Patil Group manufactures W clamps using precision engineering and tested spring steel—built for long service life, safety, and performance across diverse track conditions.

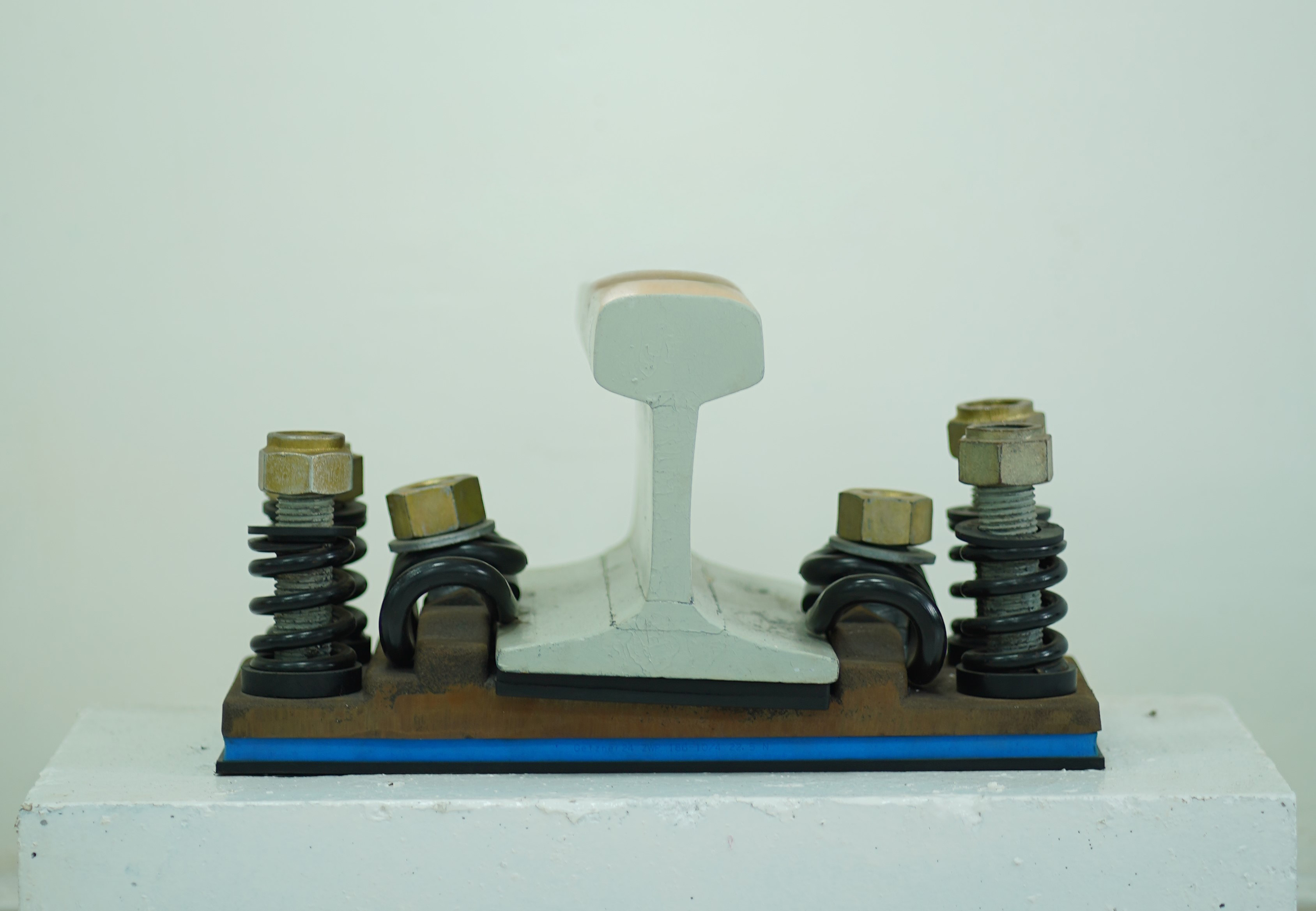

System 336 Assembly (SKL 12 Clamp)

W 14 Assembly (SKL 14 Clamp)

Fatigue Testing

Our laboratories are equipped with world-class facilities including India's first fatigue testing machine for railway fastening systems. It simulates real track conditions and subjects components to millions of load cycles, with five million cycles equating to more than ten years of service life in the lab. Earlier, such advanced testing was available only in Europe — this capability now sets a new benchmark for safety and reliability in India.