Research and Development

Driving innovation in railway technology.

Innovation & Technology Solutions

Research and Development

Innovation and technology solutions

Patil Group’s R&D drives engineering-led innovation in materials and process optimisation to deliver reliable, compliant, future-ready infrastructure and railway solutions. Through Patil I-Labs, it advances AI, ML, and IoT for smart rail infrastructure, predictive maintenance, product intelligence, and continuous improvement across all verticals.

Patil I-Labs: The Intelligence Engine of Patil Group

Intelligent Systems, Smarter Insights.

Patil I-Labs is the dedicated Research & Innovation arm of Patil Group, driving intelligent systems, diagnostics, and digital transformation for railways and allied infrastructure sectors.

From Monitoring to Intelligent Insights

As rail systems grow faster, heavier, and more complex, performance depends not just on monitoring, but on intelligent insights and decision support systems.

Patil I-Labs enables:

- Monitoring to intelligent insights: converting operational data into decisions

- Trend analysis and degradation behaviour across assets and networks

- Multi-parameter risk models instead of single-threshold alarms

- Residual Useful Life (RUL) estimation and asset lifecycle information models

- Predictive and preventive maintenance through frugal intelligence

Built on Patil Group's decades of leadership in railway track engineering and manufacturing, Patil I-Labs extends the Group's capabilities from physical infrastructure to data-driven intelligence, enabling smarter, safer, and more reliable rail operations.

This approach shifts rail operations from reactive responses to data-to-decision intelligence.

Machine vision systems for automated inspection of track, rolling stock, and wayside assets

LLM-based advanced diagnostics guiding engineers from alert to resolution

IoT, AI & ML capacity building for sensing, analytics, and prediction

Network-wide, integrated platforms delivering asset-level and corridor-level insights

Where humans alone may not solve complex, multi-variable problems, technology can meaningfully aid decisions, positioning Patil I-Labs as an intelligent partner of Indian Railways.

Driving Digital Transformation

Patil I-Labs is accelerating digital transformation in the railway sector—for India and beyond by combining deep railway domain knowledge with IoT, AI, ML, and LLM-driven intelligence.

The result: safer operations, higher availability, longer asset life, and smarter rail infrastructure at scale.

Alternate material: CMA

Extensive research by the research and development team led to a composite mineral admixture (CMA), a fly-ash-based product. Fly ash not only reduces cost but also significantly enhances concrete durability.

The sleeper design using CMA has been successfully tested at national laboratories such as the Indian Institutes of Technology (IITs) and the Research Designs and Standards Organisation (RDSO).

CMA has successfully replaced 20% of the cement.

This project was recognized by the Canadian International Development Agency (CIDA) of ICMA, Canada, and is being supported through CANMET (Canada Centre for Mineral and Energy Technology).

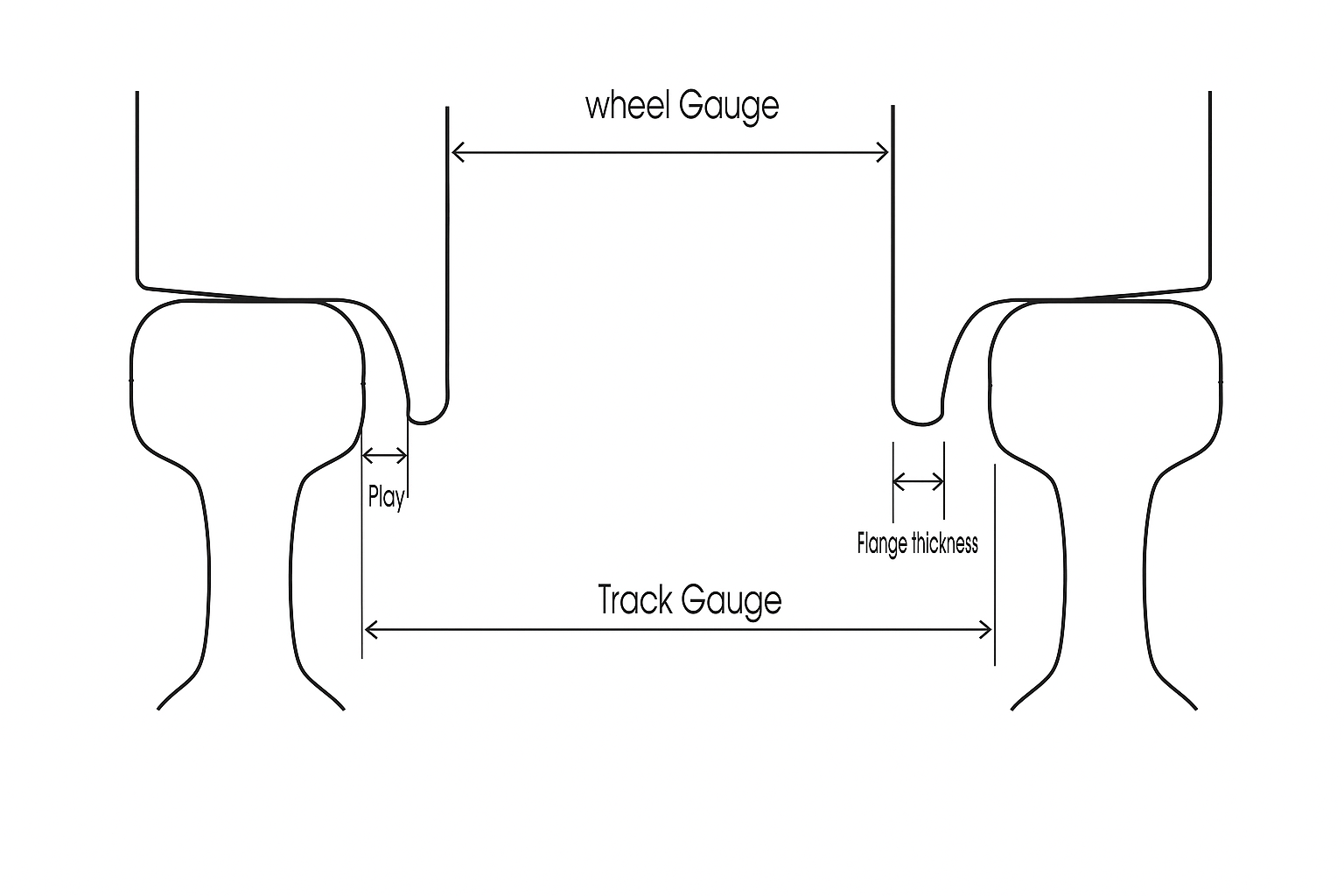

Stricter tolerance track

Existing track gauge (Broad Gauge) is 1673 mm, with tolerances of −2 to +3 (1671 mm to 1676 mm). Indian Railways is increasing operating speeds from 110 km/h to 160 km/h and beyond.

To increase speed, stricter tolerances are mandatory for better control of gauge and other track parameters. PRIL has implemented stricter tolerances of ±1 mm on wider-gauge sleepers—more stringent than European standards—laid on an Indian Railways–nominated section. Tighter parameters and reduced slack gauge decrease sinusoidal vehicle movement, improving ride index and enhancing passenger comfort and safety.

Linerless fastening system

A major problem today is rail-foot corrosion, leading to premature rail renewal due to moisture trapped in liners. Our Patil linerless fastening system addresses this issue and has been developed indigenously.

New design of concrete sleeper

The Indian Railways concrete sleeper design is about 30 years old. In that time, input materials such as cement, admixtures, and steel have improved significantly, and loading patterns and speeds have changed. In collaboration with the Railway Board, a new sleeper design was developed to meet future challenges. Given that Indian Railways uses millions of sleepers, even small economies yield large savings—one of the key drivers behind this project. With more than 25 years of experience manufacturing concrete sleepers and extensive expertise in high‑tensile steel wire, Patil Group has helped make this project a reality.

Technical advantages of the new sleeper design

Salient features of the new design:

- Adoption of M60‑grade concrete, resulting in more durable sleepers with increased lifespan.

- Increased sleeper base width reduces ballast pressure by about 10%, yielding significant savings in ballast and reduced maintenance effort.

- As railways move to higher axle‑load wagons, the new design will meet future requirements without needing an alternative sleeper.

- It envisages the use of one of the most modern strands developed in recent years, putting us on par with international prestressed concrete manufacturers.

- A special strand with higher UTS reduces steel weight per sleeper by about 25%. Under technical collaboration with Reidelle, we successfully developed the strand. The basic raw material will be produced by SSL as per the specified chemical composition. Other steel manufacturers such as Usha Martin and TISCO also have the capacity to produce it. Our technical team has completed the necessary evaluations. The strand is coded to BSI standards, and IS coding is underway.

- Reduced ballast pressure (approximately 10%) extends ballast life and decreases maintenance effort.

- In addition to these benefits, it retains the advantages of the current RDSO RT‑2496 design.